Peanut shelling equipment is a good machine,the machine is double roller, and the machine with screen and blower, so you will got the clean peanut.

The peanut sheller produced by our company has the characteristics of clean shelling and high productivity. In addition, the loss rate is low, the breaking rate is small, the structure is simple, the use is reliable, the adjustment is convenient, and the power consumption is small.

Peanut shelling machine requirements for peanuts. Peanuts are suitable for dry and wet, too dry, the rate of breakage is high, and too wet will affect work efficiency. Unshelling in winter, spray 10 kg of skinned fruit with 10 kg of warm water before shelling, and cover it with plastic film for about 10 hours, then dry it in the sun for about 1 hour to start shelling. Plastic film is used for other seasons. The coverage time is about 6 hours, and the rest is the same.

Drier peanuts (pectin) can be immersed in a large pool. Immediately after soaking, remove and cover with plastic film for about 1 day, then dry in the sun. After drying and drying, start shelling.

Voltage requirements and workplace choices. Single-phase motor households are scattered, and the wires and circuits used are not very standard, resulting in insufficient voltage for users far from the transformer. Therefore, the workplace should be close to the transformer.

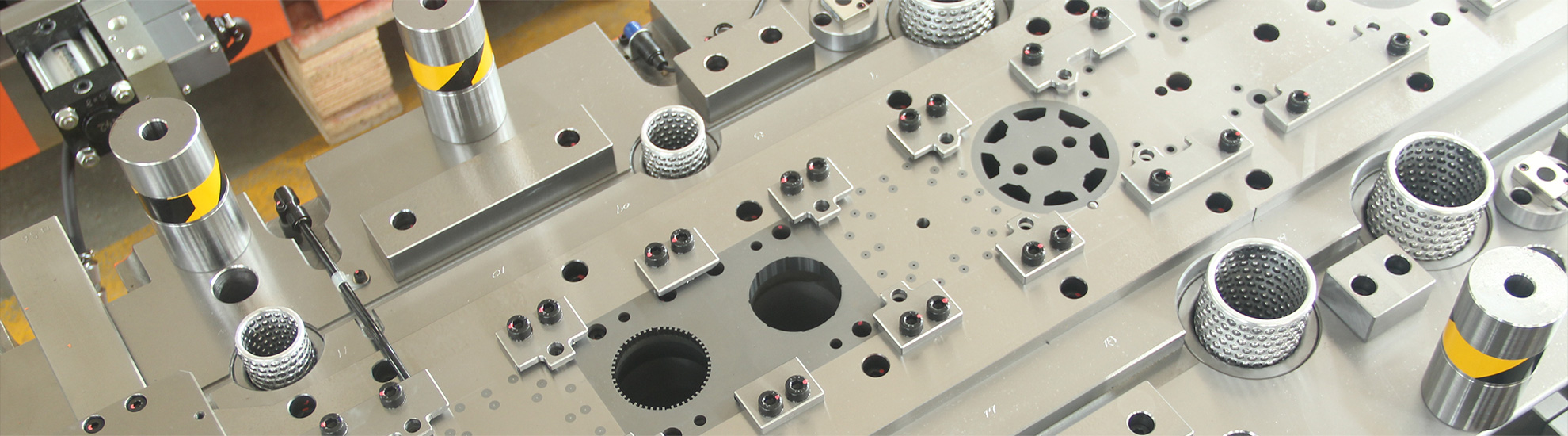

The peanut sheller consists of a frame, a fan, a rotor, a single-phase motor, a screen (two sizes), a hopper, a vibrating screen, a V-belt wheel and a transmission triangle. After the machine is in normal operation, the peanuts are quantitatively, uniformly and continuously put into the hopper, and the peanut shell is broken under the repeated impact, friction and collision of the rotor. Peanut granules and broken peanut hulls pass through a screen with a certain pore size under the rotating wind pressure and blow of the rotor. (Peanut first threshing uses a large-hole screen, and the small pebbles after cleaning are replaced with small-hole sieves. Secondary shelling) At this time, the peanut shell and the pellet are subjected to the blowing force of the rotating fan, and the light-weight peanut shell is blown out of the machine body, and the peanut grain is filtered through the sieve to achieve the purpose of cleaning.

If you want to know more about this peanut shelling machine please leave your email on our website or you can contact me with freely,we will send the machine detail and price to you.

Contacts:Cara

Email:cara@machinehall.com

Tel:0086-13015518550