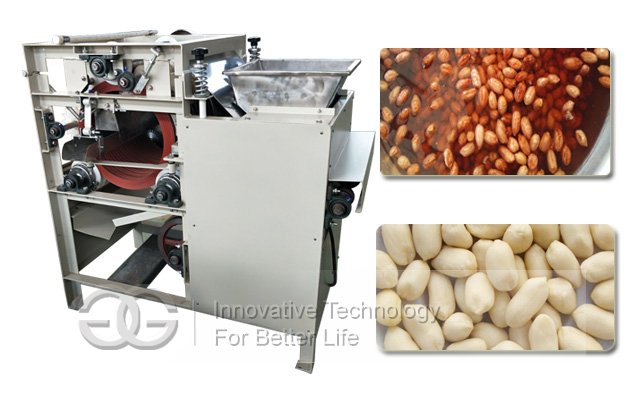

Peanut peeling machine is a peanut wet peeling machine developed and designed for deep-fried peanuts, peanut sauce and peanut-halogen products. The contact materials are all made of stainless steel (customers can request customization). The peeling rubber ring is made of high-quality rubber vulcanized with a wear of 0.1-0.4mm/10km. The service life is more than 3 times that of ordinary aprons. Peeling of peanuts needs to be immersed in hot water before peeling, and then peeling is performed. After the peeling, the whole kernel is not broken, and the protein is invariable, thus avoiding the browning phenomenon during peanut frying. Can make peanut foods in the fried process mellow, round and unique flavor. Its main technical parameters are peeling rate: 98% ± 2, broken rate: less than 3%, whole kernel rate: 85% ± 5.

The wet peanuts peeling machine is to feed the well-watered peanuts into the gap of each adjacent two rubber friction rings through a feeding mechanism, and the red skin of the peanuts is marked on the knife edge by the feeding roller and the blade, and the friction in the rubber is When the friction in the ring gap progresses and the friction advances to the pressure wheel and the limiting light bar, the peeling peanuts fall into the spiral discharge chute, and the peeling peanuts are sent to the reverse feed sheet from the feeding port by the screw shaft, finally completing the peanuts. Peeling.