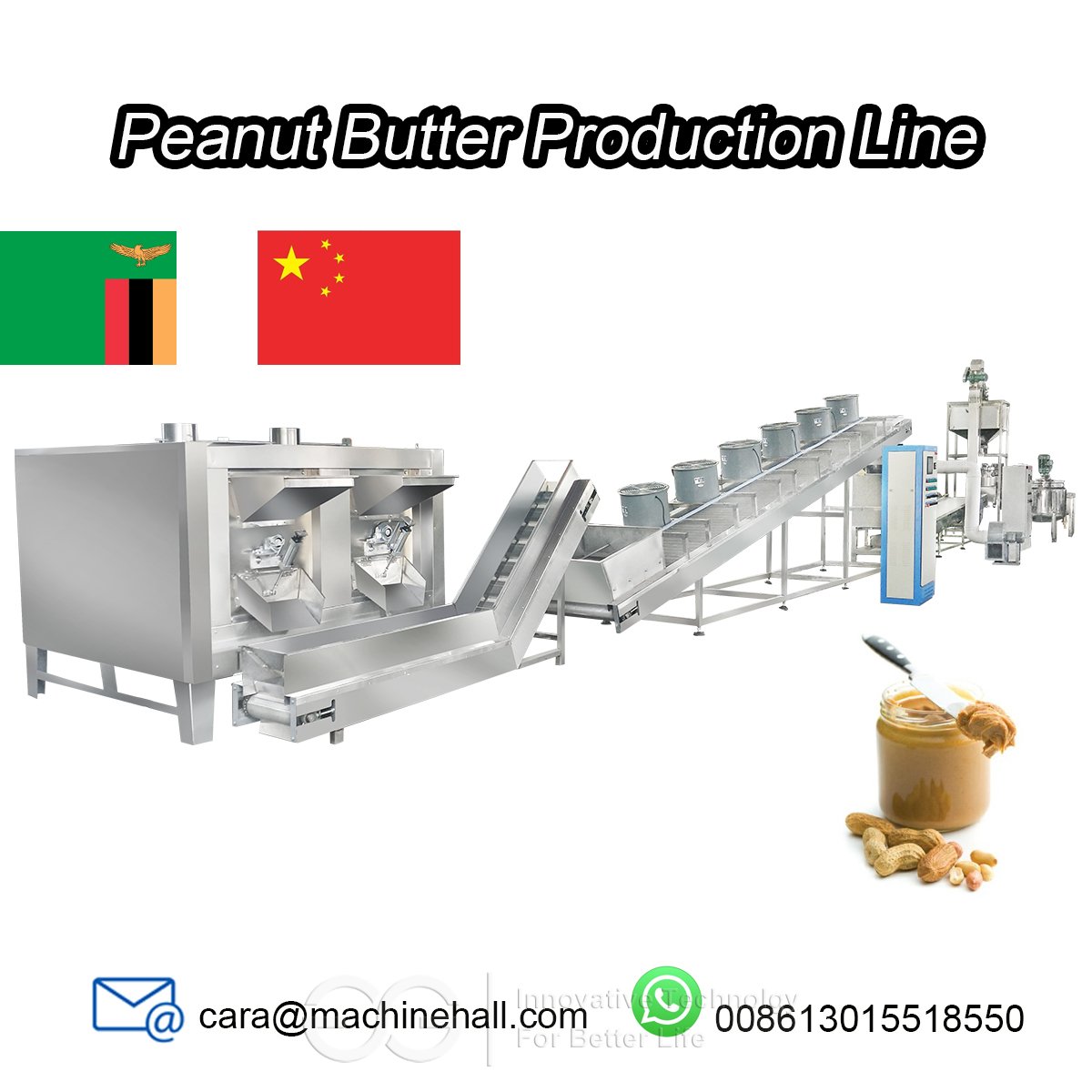

In February 2022, a Zambia customer placed an order for a peanut butter production line solution with a capacity of 500 kg/h. At present, the set of equipment has been packaged and sent to Zambia.

This is a set of highly automated peanut butter making machinery that can complete the entire production process from peanut roasting to peanut butter filling. Integrated control, easy operation, stable performance, and high product quality.

Peanut Butter Production Process:

Lifting--Roasting--Peeling--Picking-- Lifting-- Hopper-- Butter Grinding--Storage Tank-- Cooling-- Mixing--Vacuum Tank-- Storage Tank--Filling--Capping--Labeling

The whole equipment mainly consists of three parts: peanut roasting and peeling system, peanut butter grinding system, and peanut butter filling system.

1. Peanut roasting and peeling system

Peanut roasting and cooling machine: With roasting and cooling functions, it is suitable for batch continuous production, while achieving high-quality roasting. The roasted peanuts have uniform color and no damage.

Peanut peeling machine: From feeding to discharging peanuts, it can realize the three functions of peeling, separating kernel and skin, and removing peanut sprouts. High rate of broken petals and even size of peanuts.

Picking line: Pick unqualified peanuts so as not to affect the taste of peanut butter.

2. Peanut butter grinding system

Peanut grinding machine: Effectively emulsify, disperse, homogenize and crush peanuts to achieve superfine crushing and emulsification effects. The fineness of the finished peanut butter can reach 100 mesh.

Storage tank: Temporarily store the peanut butter and let the temperature drop to air temperature.

Peanut butter cooling machine: Pass in the cooling water to continuously take away the heat transferred from the peanut butter, so that the high-temperature peanut butter is slowly cooled and cooled.

Mixing tank: Make the peanut butter more even.

Vacuum degassing tank: Degas peanut butter before filling to inhibit browning, oxidation of pigments, vitamins, aroma components and other substances, and prevent quality degradation.

3. Peanut butter filling system

Peanut butter filling machine: Fill the peanut butter into the bottle. The filling volume is controlled according to time, the filling volume is accurate, and it also has a counting function.

Capping machine: Compatible with a variety of bottle caps of different shapes and sizes. Compatible with a variety of bottle caps of different shapes and sizes.

Labeling machine: affix the label to the bottle, and the labeled object will be transported to the next process or container by the labeling machine conveyor belt.

This set of peanut butter production lines is very popular all over the world and has been sold to the United States, Lubin, Britain, Ghana, Portugal, and other countries.

Contact me to get more details and price.

Contacts: Cara

Email:cara@machinehall.com

Tel:0086-13015518550

Contact me to get more details and price.

Contacts: Cara

Email:cara@machinehall.com

Tel:0086-13015518550