In the fast-paced and competitive chocolate industry, manufacturers are always looking for ways to enhance production efficiency, maintain consistent quality, and lower labor costs. Our advanced chocolate depositing equipment is specifically designed to meet these demands, providing high precision, automation, and versatility to optimize production and maximize yield.

Advanced Precision Control for Consistent Production

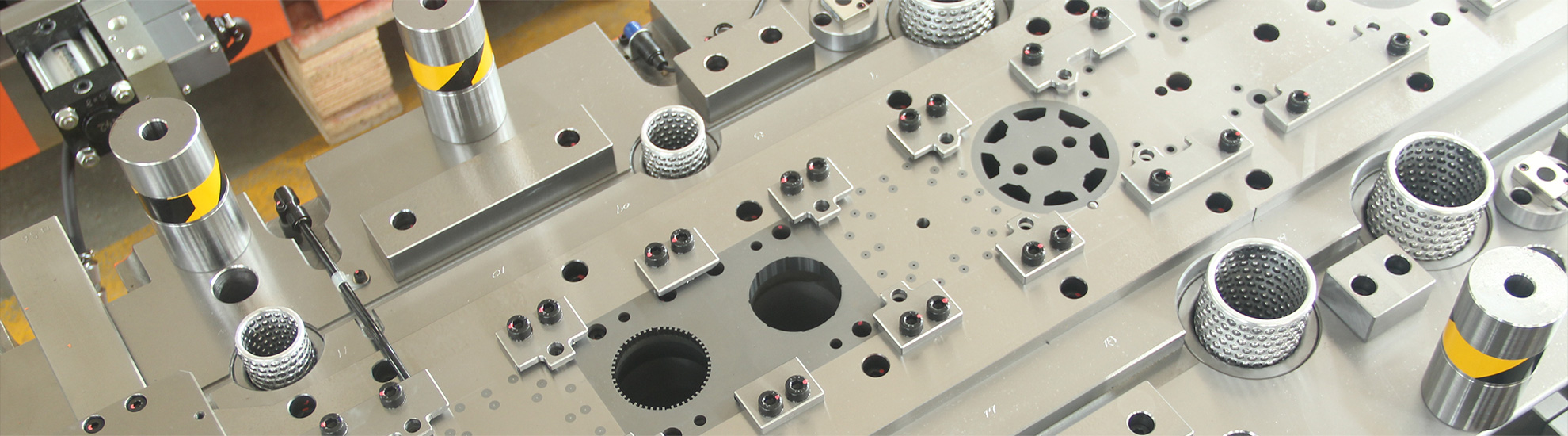

This machine utilizes an advanced servo motor control system with variable frequency adjustment to precisely regulate the depositing stroke. This ensures consistent chocolate dosing, minimizes material waste, and enhances production efficiency. Additionally, proximity switches enable precise mold positioning, eliminating errors and ensuring reliable operation at every stage.

Compliance with International Food Safety Standards

Food safety is a top priority for chocolate manufacturers. Our depositing equipment is built with food-grade stainless steel, and all contact surfaces comply with international hygiene regulations. The automated system minimizes human contact with the product, reducing contamination risks and ensuring a safe production environment.

Automation for Reduced Labor Costs

Traditional chocolate depositing often involves manual processes that are time-consuming and inconsistent. Our fully automated system streamlines production by integrating mold heating, precise depositing, and vibration functions, minimizing the need for manual handling. The intuitive user interface ensures quick and easy operation, reducing training time and lowering labor costs while maintaining consistent quality.

In summary, our intelligent chocolate depositing equipment helps manufacturers boost efficiency, reduce costs, and maintain high product quality. Whether you're a small artisanal chocolate brand or a large-scale industrial producer, this machine is a valuable addition to your production line, helping you stay competitive in the market.